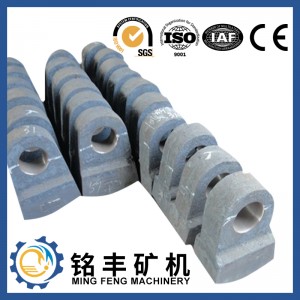

Sand casting rauj shredder crusher spare qhov chaw

Txheej txheem cej luam:

| Qhov Chaw Keeb Kwm | Hunan, Suav | Cov ntsiab lus ntawm Mn | 26% |

| Khoom npe | Rauj | Tshuab Hom | Crusher |

| Khoom siv | hlau tawv;carbide;cemented carbide;kentanium;wimet;sintered-carbide;nyuaj alloy;Carbide alloy Cr20Mn2, Cr26Mn2 | ||

| Hom kev ua haujlwm | Casting | Daim ntawv thov | Ore Mining |

| Daim ntawv pov thawj | ISO9001 | Txoj Kev Xeem | Hardness test thiab flaw detector test |

| Tswj | Spectrometer tshuaj ntsuam xyuas thiab tswj thaum tsim khoom | ||

Daim ntawv thov:

Siv dav hauv kev lag luam mining, metallurgical kev lag luam, kev tsim kho kev lag luam, tshuaj lom neeg kev lag luam thiab silicate kev lag luam rau crushing nyuaj thiab nruab nrab hard ore thiab pob zeb, xws li hlau ore, licommonne, tooj liab ore, sandstone thiab hais txog.

Cov txiaj ntsig khoom:

Piv nrog rau cov khoom lag luam dav dav, peb cov khoom lag luam du nto, siab hnav tsis kam thiab lub neej ntev dua.

Hauv qab no yog peb cov khoom siv ib txwm muaj, peb kuj tuaj yeem kho raws li koj qhov kev thov

High Manganess Casting Material Chemical muaj pes tsawg leeg

| Khoom siv Code | C | Mn | Si | Cr | P | S | ||||||||

| ZGMn13Cr2 | C: 1.0 ~ 1.3 | Hnub: 11-14 | Si: 0.3 ~ 0.6 | Cr: 1.7-2.4 | P: ≤ 0.05 | S: ≤ 0.03 | ||||||||

| ZGMn18Cr2 | C: 1.1 ~ 1.4 | Hnub: 17-20 | Si: 0.3 ~ 0.6 | Cr: 1.7-2.4 | P: ≤ 0.05 | S: ≤ 0.03 | ||||||||

| ZGMn22Cr2 | C: 1.1 ~ 1.4 | Hnub: 20-24 | Si: 0.3 ~ 0.6 | Cr: 1.7-2.4 | P: ≤ 0.05 | S: ≤ 0.03 | ||||||||

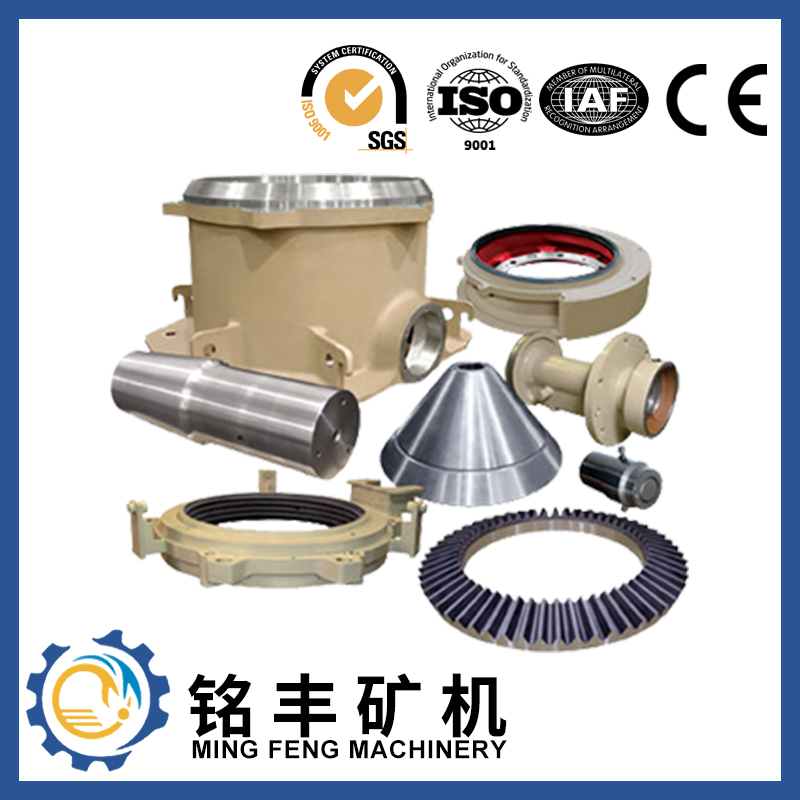

Crusher qhov chaw:

Peb muaj precision machined hloov crusher spare qhov chaw xws li lub taub hau, tais, lub ntsiab ncej, lub qhov (socket) liner, qhov (socket), eccentric bushing, taub hau bushings, iav, txee ncej, countershaft bushing, countershaft vaj tse, mainframe lub rooj liner thiab ntau dua, peb tuaj yeem pab txhawb koj lub tshuab tag nrho rau mechanical spare qhov chaw.

Vim li cas thiaj xaiv peb?

1.30 xyoo ntawm kev tsim khoom, 6 xyoo ntawm kev lag luam txawv teb chaws

2.Strict zoo tswj, Muaj chaw kuaj

3. ISO9001: 2008, BUREAU VERITAS

KUB-muag khoom

Ua ntej, Kev Nyab Xeeb Guaranteed